SENNEBOGEN

- Used

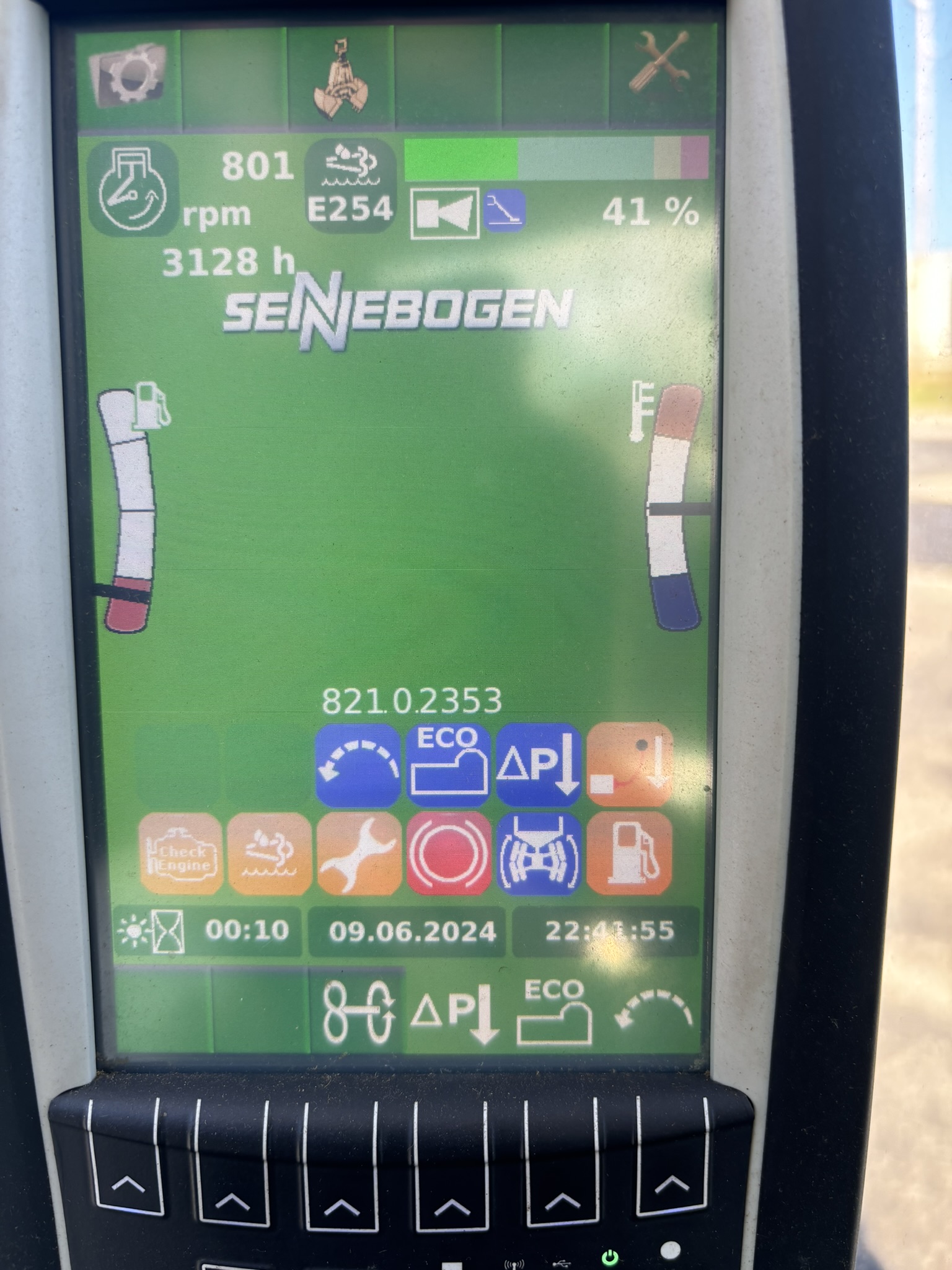

- 3128

- 52,800 lbs

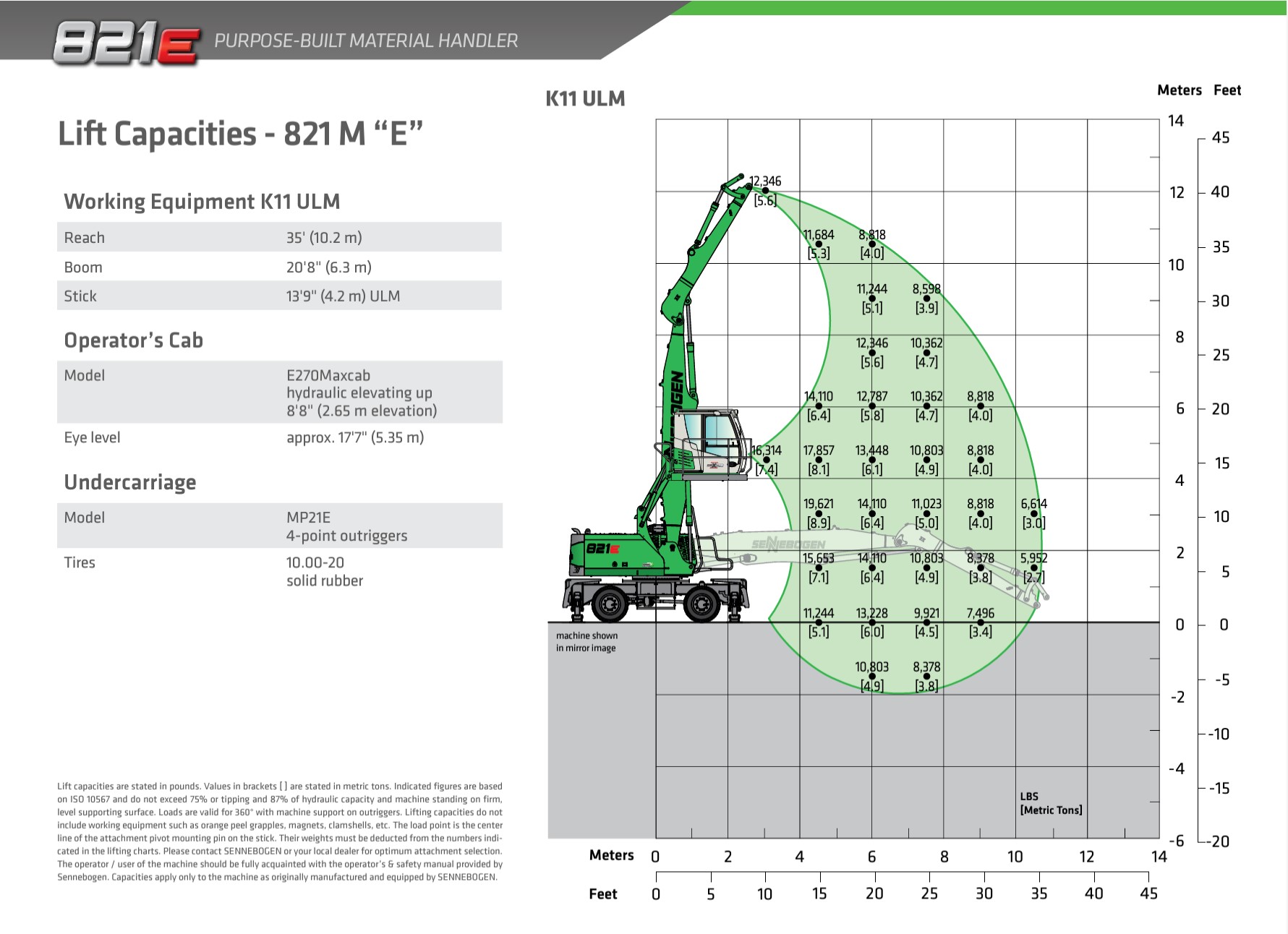

- K11 ULM - 34.3'

- CUMMINS QSB 4.5 C160, 104kW/2200 rpm, Tier 4 Final

- 821.0.2353

- Eye level up to 18.4'

- Request a Price

DESCRIPTION

This used 821M wheeled material handler is configured w/ a K11 ULM stick/boom combination, it has a reach of 34′ and weighs 52,800 lbs. It’s ULM stick is ideal for waste & recycling station duties.

When you purchase a used material handler from Sennebogen North America you are fully supported by the Factory with $55 million in parts inventory in North Carolina, 24/7 on-call Parts ordering, and even Free Training for your Service Techs at the Factory. You are also supported by the industry’s largest Dealer and Authorized Service Provider Network. You can check out all the Service options in your area HERE

The machine is located in South Carolina. Contact us for a machine and freight quote.

DETAILED SPECS

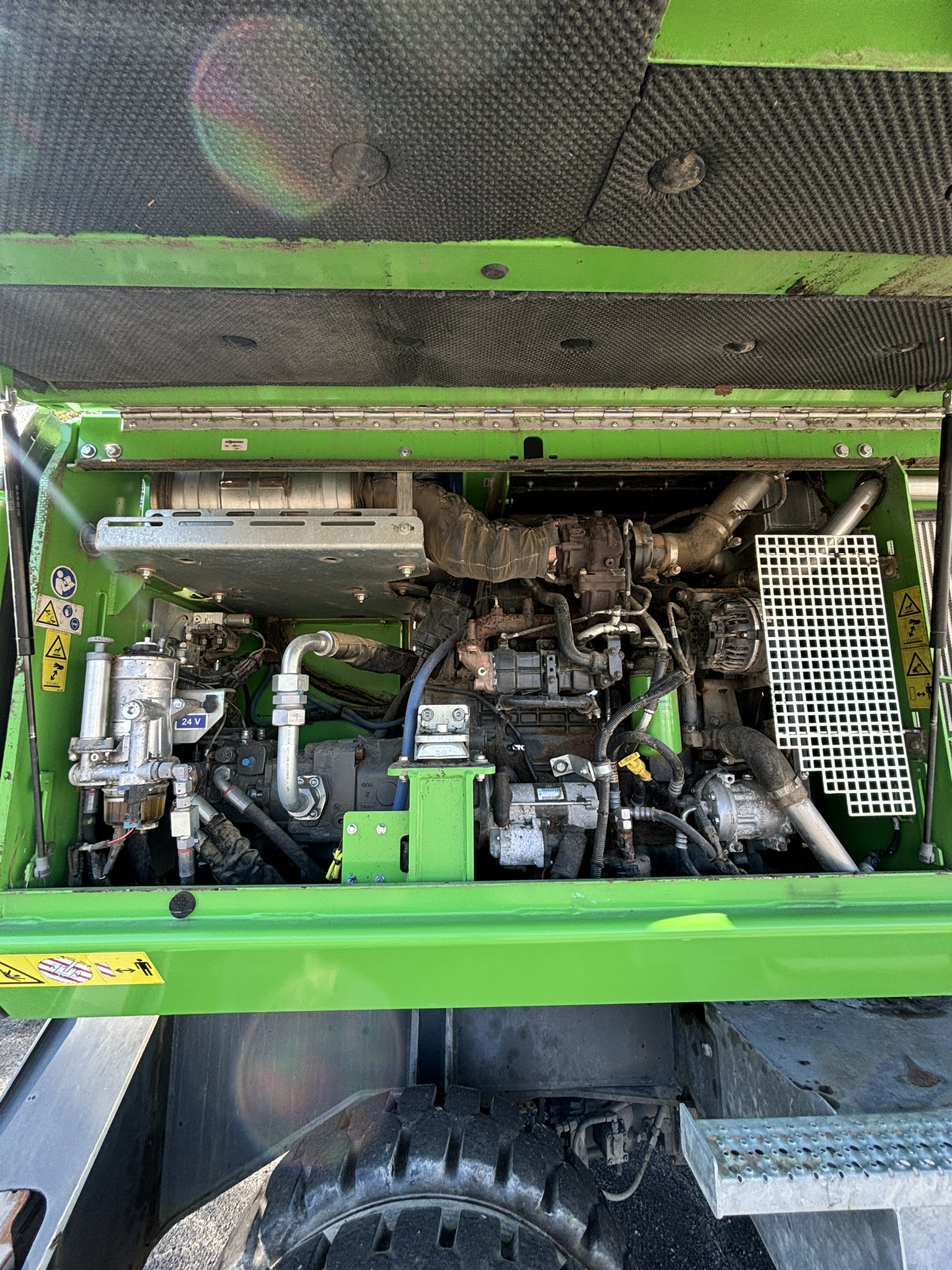

CUMMINS QSB 4.5 – C140, 104kW/2200 rpm, emissions according to US EPA Tier 4 final/EU stage IV, water cooled including electrically heated water separator with fuel prefilter 24V

• Air pre-cleaner, precleans approx. 98% of abrasive smut

• Automatic idle speed stop for diesel engine

• Eco-mode for diesel engine

• SENNEBOGEN MAXCAB – cab with sliding door

• Heating- Climate automatic with central control elements

• SENNEBOGEN control & diagnostic system SENCON

• Counter rotation of ventilator for cleaning the cooler

• Automatic central lubrication for equipment and slewing ring raceway

• Lighting system 1: 2 pcs. H4 headlights mounted in the upper carriage-frame on the front side left and right, 2 rear lights and 2 halogen lights integrated in the left front side of the cab roof. LED headlight with magnetic fixing support and 5m of cable for flexible connection in maintenance area

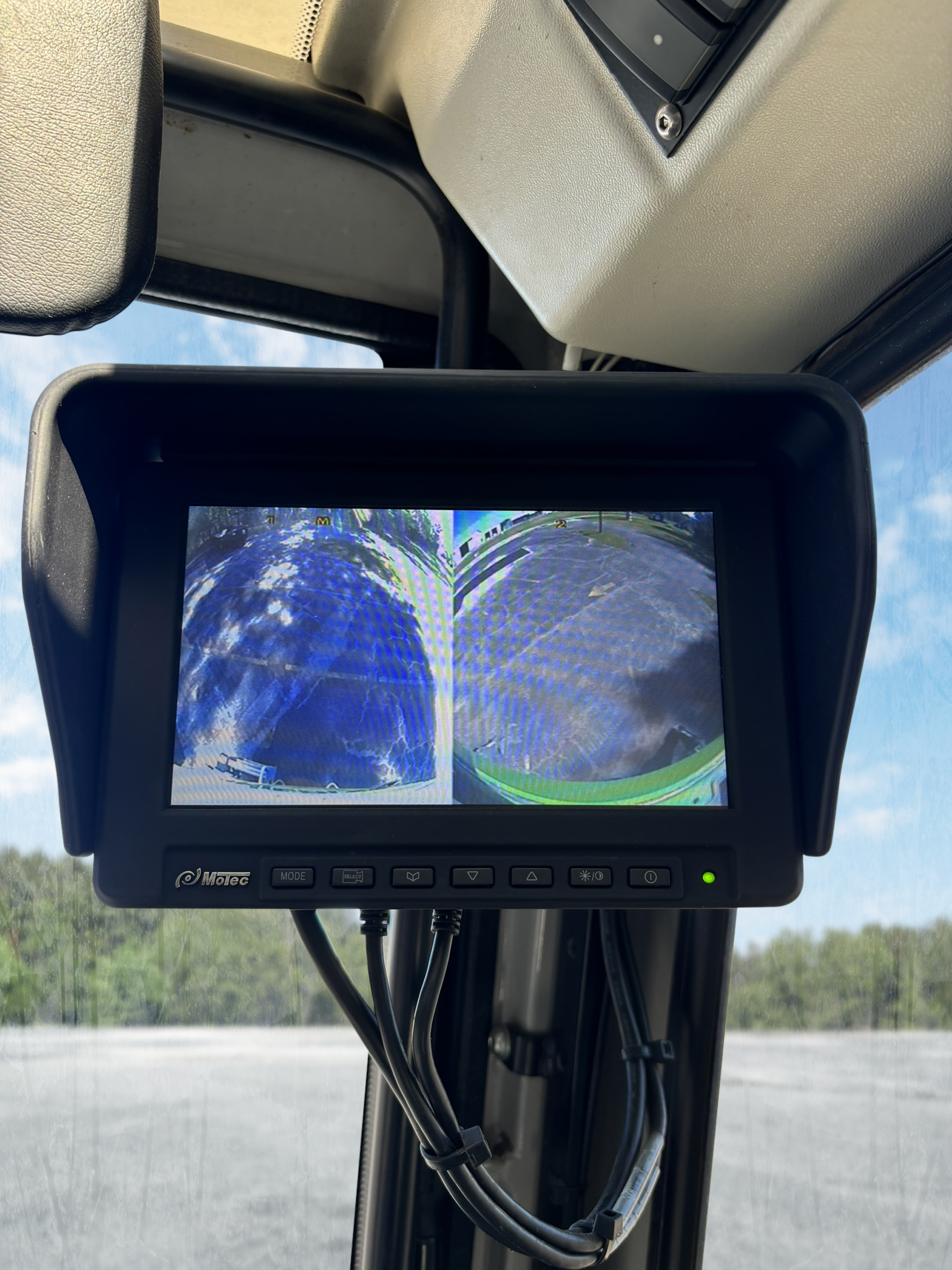

• Camera system – base package with 2 cameras includes 1 color monitor 7”, monitor with 4-way split, up to 4 cameras expandable, 2 cameras with 115° field viewing angle for rear view camera right side of the machine

• Emergency control function to ensure machine availability for limited operations by bridging the main functions

• Tool kit

• Wheeled undercarriage MP21E for diesel machines with 4-point-stabilizers, all-wheel-drive and two-stage powershift transmission.

• Solid rubber tires, 10.00-20 (8 units) with intermediate ring

• Joystick-steering (only wheeled machines)

• Cab elevation type E270 for SENNEBOGEN MAXCAB, infinitely adjustable up to 2.7m via hydraulics

• SENNEBOGEN MAXCAB operator’s cab with sliding door, resiliently mounted, tinted safety glass, tiltable front window, skylight,

wiper/washer system for front window, 2 halogen lights integrated in the front of the roof.

• Air suspended operator’s seat with support for intervertebral disc, seat heating and headrest for driver´s seat

• 2 inch seat belt – standard

• Windscreen wiper for lower cabin front window with washer system

• Sun protection for skylight

• Sliding window in driver’s door for MAXCAB operator’s cab

• Radio with USB and SD port, MP3 and Bluetooth

• Standard lubricants for operation range between -20°C and +40°C, for diesel machines

• Information: hydraulic oil type needs to be defined separately

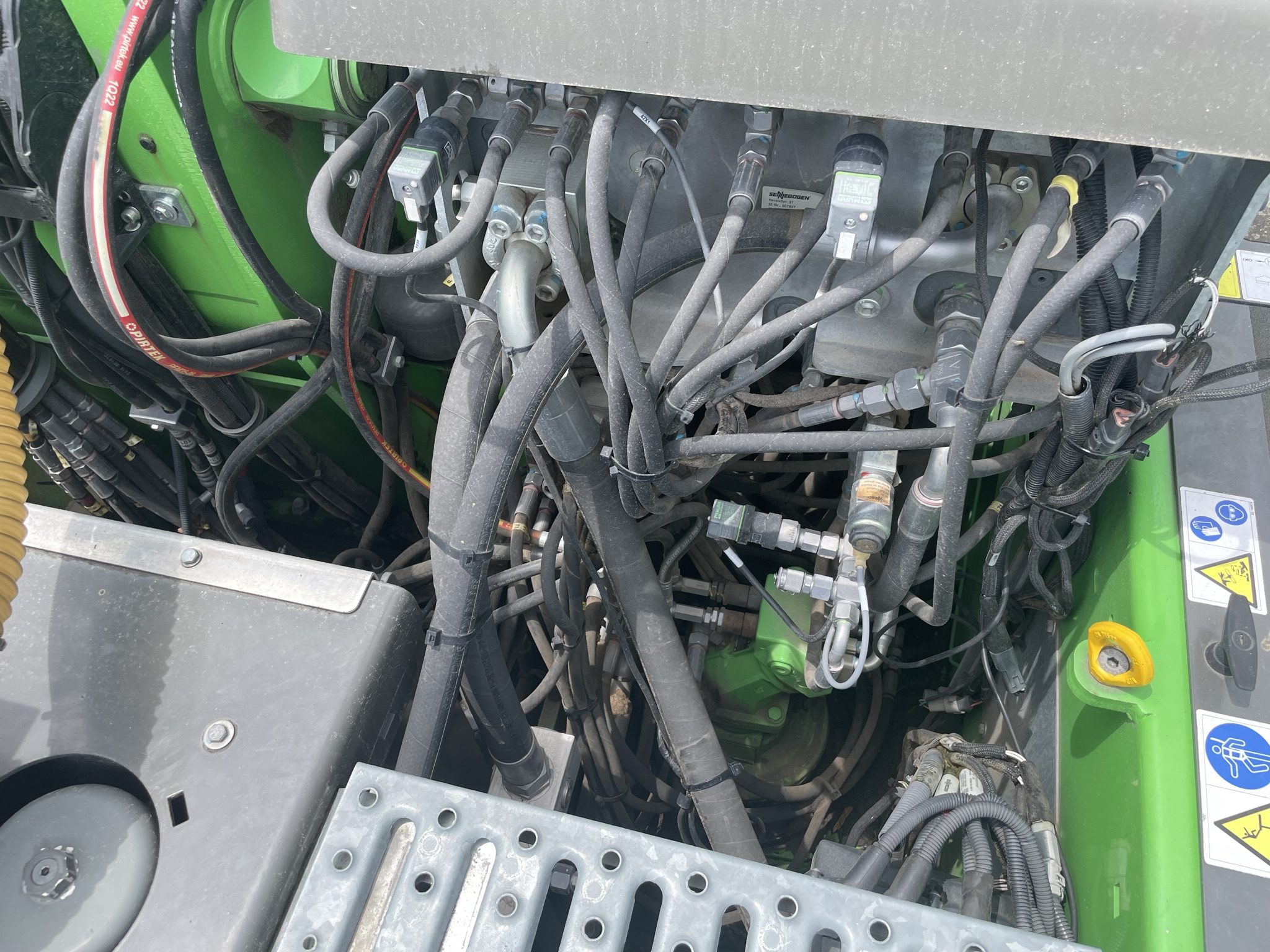

• Hydraulic oil Shell Tellus S2 VA 46

• SENNEBOGEN Hydro-Clean: Hydraulic micro filter system with water absorption contamination indicator (higher oil purity and

extended oil service life), equipment recommended especially when biodegradable oil is used

• Special materials handling boom type K11 ULM consisting of: compact boom 6.3m straight and grab handling stick 4.2m straight with

ULM reversing mechanism

• End position shut off for stick in function, safety check valves for boom and stick cylinders

• Quick change couplers (bolted type) with counter pieces for grab open/close and grab rotating

• Pressure indicator (boom cylinder) with Barograph display in the SENCON and acoustical warning, deactivation possible.

• (1b) ULM hydraulics for bucket cylinder operation consisting of: standard hydraulics for operation of a grab with fixed oil quantity and oil pressure. Additional hydraulic valve and additional piping for operation of the bucket cylinder ULM, appropriate for attachments

e.g. sorting grab

• 2 LED headlights mounted on the stick: 1 pc on left side, 1 pc on right side

• 1 LED headlight mounted on the compact boom down side

North American specs that will be added prior to shipment

Front and skylight guards

Under carriage protection

Upper carriage handrails

Cab Catwalk

Travel Alarm

Ball Valves at end of stick

Listed are the machine’s original specs from the factory, we can’t guarantee accuracy as it is a used machine.

AFTER-SALES SUPPORT

All of our Used machines receive the same level of after-sell support as our new machines.

Customer Direct

We work directly with you when it comes to selling our machines and providing after-sell support. No other manufacturer gives you direct access

Minimize Downtime

Uptime is priority No. 1 at SENNEBOGEN and we have developed specialized programs and services to keep you up & running smoothly.

SERVICE NETWORK

SENNEBOGEN has built the industry’s largest network for factory-trained technicians, offering you more choices to ensure the best possible support for your SENNEBOGEN, throughout the life of the machine.

Uptime Kits

SENNEBOGEN is the only manufacturer on the market that has specific kits to provide quick resolution for minor issues that can cause a machine to go down

Preventive Maintenance Kits

Parts Inventory

We have $50M in parts inventory in Stanley, NC with a 95% order fill-rate. When we run into a situation where we do not have a part in-stock we will air-freight it from Germany.

24-Hour “on call” parts service

We have a 24-hour “on call” parts service which you can call if a machine is down, and you need a part asap. Our “on call” parts rep will arrange for a hotshot truck to arrive at our warehouse and ensure the part is in route asap. (Call parts @ 704-347-4911).