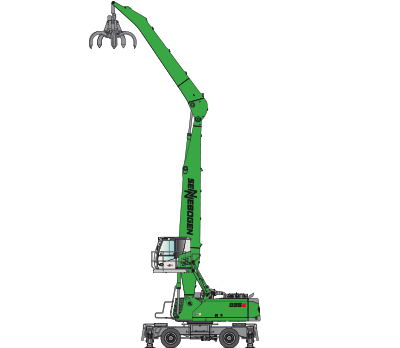

MATERIAL HANDLER FOR SCRAP AND PORT HANDLING

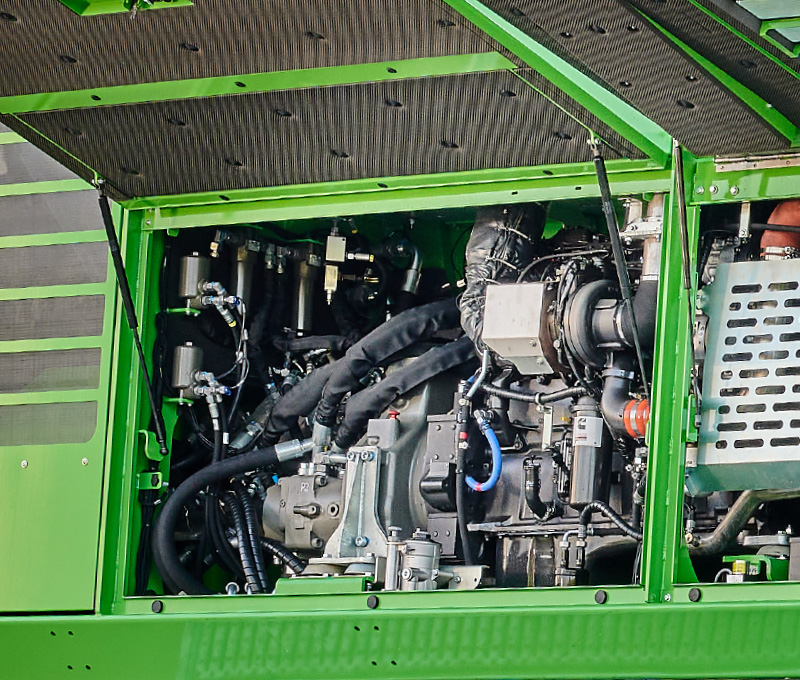

The design of the 835 E series machine impresses with its large range of equipment options, high operator comfort, and optimized technology. The Green Efficiency Model combines proven high performance with low fuel consumption, maximum operating comfort and safety features for both the operator and the machine.