SENNEBOGEN

- Certified Used

- 9

- 84,000 Lbs

- K17 - 55'9"

- CUMMINS Engine B6.7, 129 kW / 2,200, Tier 4 Final

- 830.0.3773

- Eye level up to 19′

- Request a Price

DESCRIPTION

This Certified Used Sennebogen comes with our standard 12-Month/2,000 Warranty.

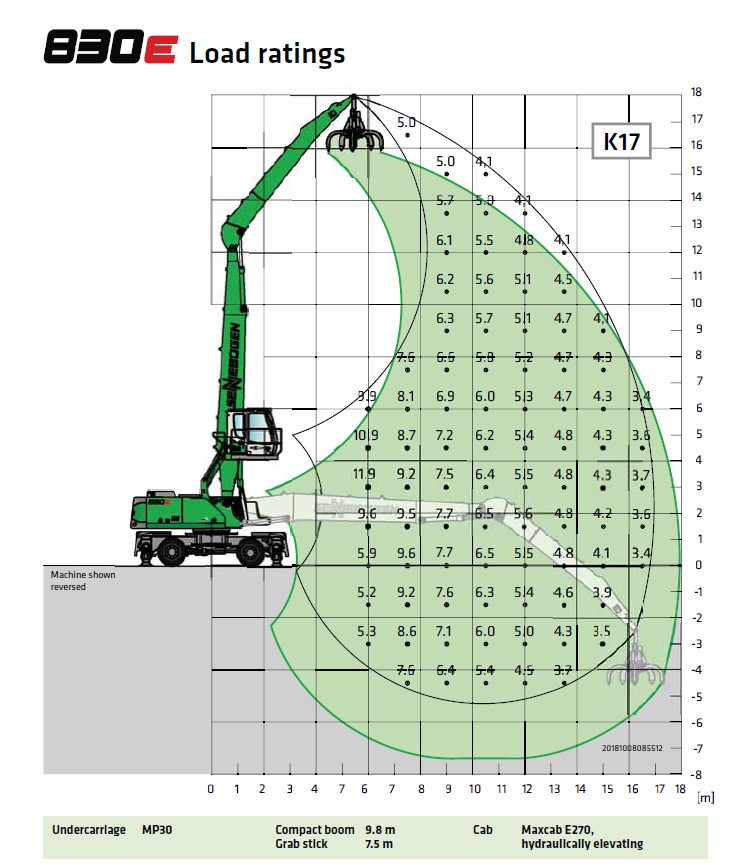

This used Certified Used Sennebogen 830 wheeled material handler has a K17 stick/boom with a reach of 55’9″ and weighs 84,000 pounds.

When you purchase a used material handler from Sennebogen North America you are fully supported by the Factory with $55 million in parts inventory in North Carolina, 24/7 on-call Parts ordering, and even Free Training for your Service Techs at the Factory. You are also supported by the industry’s largest Dealer and Authorized Service Provider Network. You can check out all the Service options in your area HERE

Contact us for a machine and freight quote.

DETAILED SPECS

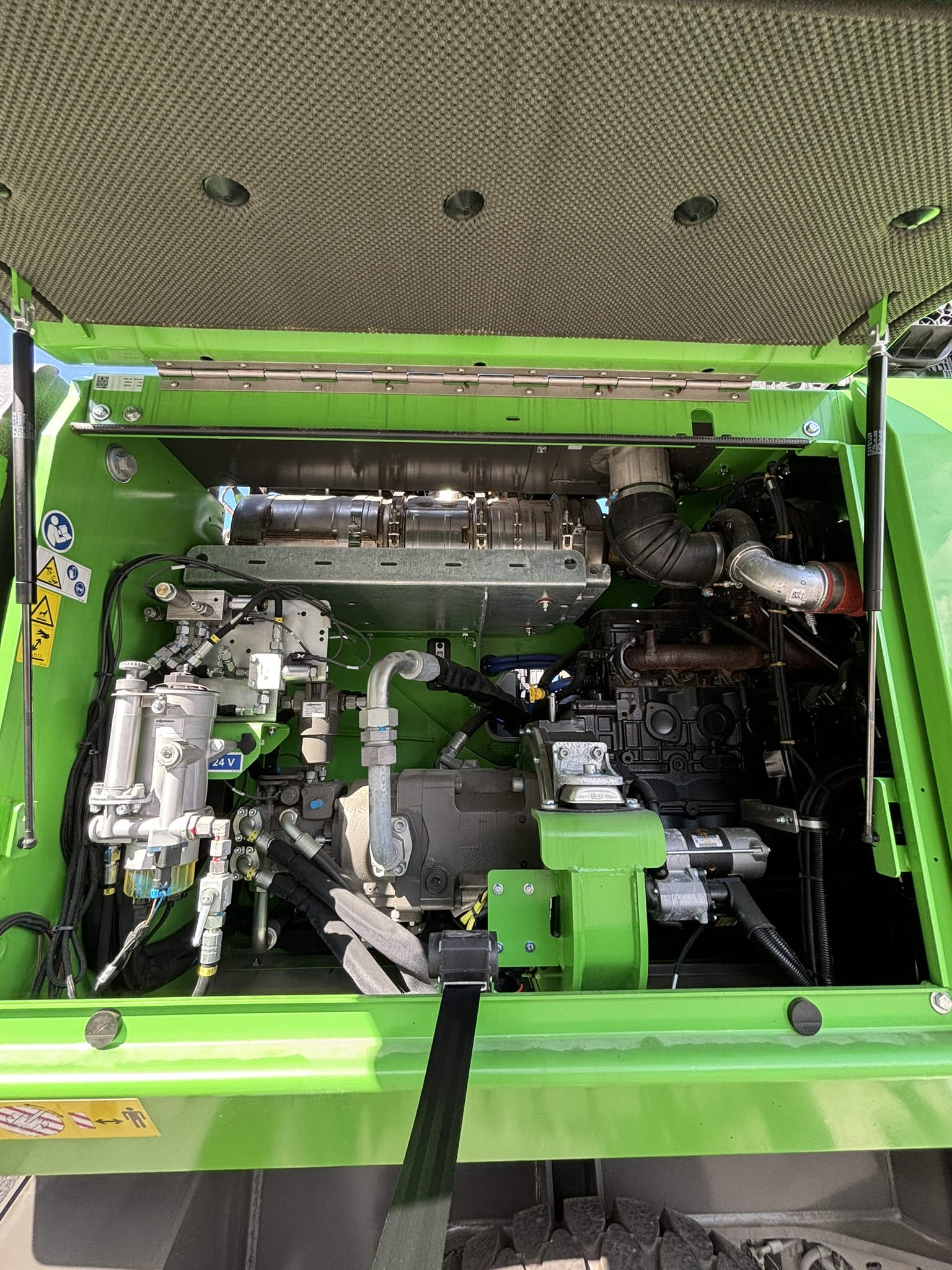

Engine

Cummins B6.7 diesel engine (6 cylinder) with direct injection, water cooled (TIER 4f emission)

Engine output 230 HP (168 kW) @ 2,000 rpm

Turbo intercooler direct driven

Water cooler hydraulically driven, reversible

Automatic idle-stop control and eco-mode for diesel engine

Hydraulic System

Computer free, state-of-the-art load-sensing with flow-on-demand control

Hydraulic cooler hydraulically driven, reversible

Hydro-Clean filtration system with water absorption and contamination indicator

Upper Carriage & Swing System

Torsion free, precisely machined upper carriage frame

High torque axial piston swing motor

Large dimensioned, external teeth swing bearing with removable protection cover

Automatic central lubrication system for upper carriage and swing bearing

Manual pinion lubrication system for swing bearing

Handrail on top of upper carriage

Fire extinguisher set (1x cab, 1x storage compartment) – brackets installed, extinguisher shipped separate to dealer

Light Package consisting of: 2x halogen in cab roof, 2x in frame

Additional 0.75t counterweight

Operator’s Cab “maXCab”

Hydraulic elevating cab system “E270″ (elevation: 8’8”)

Catwalk with handrail beside cab

“maXCab” with sliding door and door window as sliding window, sunshade, floor mat

Skylight of bullet proof glass

Windshield of bullet proof glass (fixed / no tilt out)

Front & top cab protection guard

Automatic climate control with AC, heater and defroster

AM/FM radio with MP3/Bluetooth

SENCON visual and acoustic diagnostic system for monitoring all essential machine functions

Air suspended and adjustable operator’s seat incl. armrests, seat heater, headrest, seat belt

Camera system with display in cab

LED light package on cab, rear

Strobe light mounted on cab

Operator’s & Maintenance manuals incl. hydraulic & electric schematics (1x print / 1x digital)

Spare Parts catalogue (1x print / 1x digital)

Working Equipment

K17 – reach 56’6″ / purpose built material handling working equipment (boom position I)

Straight boom, with end stop monitoring system and limit switches

Straight stick”, with end stop monitoring system and limit switches

Boom & Stick cylinders equipped with safety check valves and end position dumping

Light Package consisting of: 1x at boom, 2x at stick

Attachment open/close and rotate hydraulic circuits and lines installed up to the end of the stick (ball valves)

Under Carriage

Rubber tired under carriage MP30E with 4-point outriggers (width 9′)

Automatic unlock of oscillating axle if upper carriage in longitudinal direction to under carriage

Solid rubber tires 12.00-20 (8 units) inclusive intermediate protection ring

Steering via joystick, front wheel steering

All wheel drive via variable hydraulic motor with 2-stage shift transmission

Protection guard for under carriage to protect transmission, hydraulic motor and drive shafts

2-circuit servo brake system with additional safety brake

Centralized lubrication points (front & rear) for lubrication of under carriage components

Audible travel alarm while driving machine (forward & backward)

Tool box w/ basic tools, stick pin, grease gun, wheel chock, green & gray touch up paint located in under carriage tool box

Magnet System

20 kW Baldor generator, hydraulic driven with Hubbell controller

Plug in front of stick to hook up magnet, magnet connection cable in under carriage tool box

Magnet suspension link

AFTER-SALES SUPPORT

All of our Used machines receive the same level of after-sell support as our new machines.

Customer Direct

We work directly with you when it comes to selling our machines and providing after-sell support. No other manufacturer gives you direct access

Minimize Downtime

Uptime is priority No. 1 at SENNEBOGEN and we have developed specialized programs and services to keep you up & running smoothly.

SERVICE NETWORK

SENNEBOGEN has built the industry’s largest network for factory-trained technicians, offering you more choices to ensure the best possible support for your SENNEBOGEN, throughout the life of the machine.

Uptime Kits

SENNEBOGEN is the only manufacturer on the market that has specific kits to provide quick resolution for minor issues that can cause a machine to go down

Preventive Maintenance Kits

Parts Inventory

We have $50M in parts inventory in Stanley, NC with a 95% order fill-rate. When we run into a situation where we do not have a part in-stock we will air-freight it from Germany.

24-Hour “on call” parts service

We have a 24-hour “on call” parts service which you can call if a machine is down, and you need a part asap. Our “on call” parts rep will arrange for a hotshot truck to arrive at our warehouse and ensure the part is in route asap. (Call parts @ 704-347-4911).